Rcc Compound Wall Mould

Price 95 INR/ Ton

Rcc Compound Wall Mould Specification

- Life Span

- 5-8 years

- Mold Base

- Fine Quality Steel

- Molding Material

- High-grade Concrete

- Cavity

- Single or Double

- Shaping Mode

- Compression Mould

- Material

- Mild Steel/Alloy Steel

- Tolerance

- 1 mm

- Mould Weight

- 80-120 kg (Approx.)

- Mould Life

- 80,000+ cycles

Rcc Compound Wall Mould Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Average Load Time

- 5-10 min per cycle

- Supply Ability

- 15 Kilograms, , Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard

- Main Domestic Market

- All India

About Rcc Compound Wall Mould

- With latest vibrating system. So, result of the wall panels & wall poll is superior quality. Because of vibrating system there are no holes or sos in RCC casting

- The thickness of the wall panel is maintained in accurate in thickness.

- Our plant gives more production in small place because of, Our vertical casting system.

- We are giving wire tightening system, So all wire of the wall panels is tightening to gather. In perfect required strength.

- Our poll has facility to mounting Angle bracket for wire fencing.

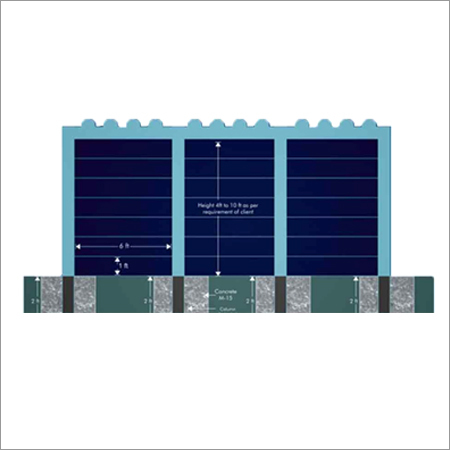

Technical Details of the Wall Panel

- Wall Panel (Slab)

- Length of Panel 2134 mm ( 7 ' )

- Thickness of Panel 48 mm ( 2 " )

- Height of Panel 300 mm ( 12 ")

- Height Thinkers And Length a The Wall Panel (Slab) Can Be Developed and Produced As Per Your Requirement

- Poll (Colom)

- Size : 150 mm + 150 mm

- Length As per your Requirement

- Production in a Single Bench : 136 Wall panel can be produced in single bench.

- Space required box. : 5' x 65' Space required for line of 8 moulding.

Technical Specifications:

| Usage | Gardens, Lawns etc |

| Material | Concrete |

| Built Type | Panel Build |

Advanced Mould Engineering for Lasting Performance

Our RCC Compound Wall Mould utilizes fine-quality steel as the base and high-grade concrete for shaping. Precision tolerance (1 mm) guarantees flawless panels every cycle. Designed to withstand rigorous production, the mould lasts 80,000+ cycles and offers a lifespan of 58 years, making it a dependable choice for high-volume manufacturing environments.

Customizable Designs and Versatile Use

Choose from a variety of mould sizes based on your wall panel designs, with plain or textured patterns to suit architectural needs. Compatibility with manual or hydraulic vibrator machines offers versatility in panel production. The robust construction and superior surface finish ensure panels are both visually appealing and structurally sound.

FAQs of Rcc Compound Wall Mould:

Q: How is the RCC Compound Wall Mould maintained for extended use?

A: To ensure the mould remains in optimal condition, simply perform periodic cleaning to remove any concrete residue. Thanks to its corrosion-resistant steel construction, minimal maintenance is required beyond routine cleaning.Q: What are the customization options available for this mould?

A: The mould size can be fully tailored based on your specific compound wall design. Additionally, you can choose between plain or textured patterns and opt for a single or double cavity as per your production requirements.Q: When is this mould best suited for use?

A: This mould is specially designed for outdoor and industrial environments, making it the ideal choice for RCC compound wall panel production under demanding conditions.Q: Where can this mould be installed and utilized?

A: The mould is compatible with both manual and hydraulic vibrator machines, giving you flexibility to use it in various manufacturing setups, either on-site or within factory settings across India.Q: What is the expected lifespan and mould life under regular operation?

A: With proper care and periodic cleaning, the mould is built to deliver 80,000+ production cycles and can last between 5 to 8 years, depending on usage intensity.Q: How does the mould benefit panel producers?

A: Panel manufacturers benefit from high dimensional accuracy (1 mm tolerance), low maintenance requirements, exceptional durability, and versatility in mould design. This all leads to higher productivity and superior quality wall panels.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Compound Wall Moulds Category

Custom Compound Wall Mould

Price 60 INR / Ton

Minimum Order Quantity : 1 , , Ton

Material : Other, HighGrade Steel / Alloy

Life Span : Up to 10 years with proper maintenance

Mould Life : 50,000 100,000 cycles

Tolerance : 0.01 mm

Compound Wall Pole Mould

Price 95 INR / Ton

Minimum Order Quantity : 1 Kilograms

Material : Other, Steel Alloy

Life Span : 58 Years

Mould Life : 15002000 cycles

Tolerance : 1 mm

Iron Concrete Compound Wall Mould

Price 60 INR / Ton

Minimum Order Quantity : 1 Ton

Material : Other, Cast Iron

Life Span : Up to 6 years

Mould Life : 50008000 cycles

Tolerance : 1 mm

Pre Cast Compound Wall Mould

Price 60 INR / Ton

Minimum Order Quantity : 1 Ton

Material : Other, ABS, Steel, FRP

Life Span : 510 Years

Mould Life : 50,000 cycles or more

Tolerance : 1 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS