Custom Compound Wall Mould

Price 60 INR/ Ton

Custom Compound Wall Mould Specification

- Mold Base

- Stainless Steel

- Life Span

- Up to 10 years with proper maintenance

- Cavity

- Single / Multiple as per requirement

- Molding Material

- Plastic / PVC / Concrete

- Shaping Mode

- Injection / Compression / Casting

- Material

- High-Grade Steel / Alloy

- Tolerance

- 0.01 mm

- Mould Weight

- 80-150 kg (depending on size)

- Mould Life

- 50,000 100,000 cycles

- Dimension Accuracy

- High Precision

- Surface Finish

- Smooth, Matte or Custom Texture

- Thermal Stability

- Up to 250°C

- Customisation

- Size, Design, Logo as per client requirements

- Color Options

- Available as per specification

- Corrosion Resistance

- Yes

- Maintenance

- Easy to clean and maintain

- Application

- Precast Compound Wall Panel Production

- Usage Type

- Industrial, Commercial

Custom Compound Wall Mould Trade Information

- Minimum Order Quantity

- 1 , , Ton

- Average Load Time

- 30-60 seconds per cycle

- Supply Ability

- 15 Tons Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard

- Main Domestic Market

- All India

About Custom Compound Wall Mould

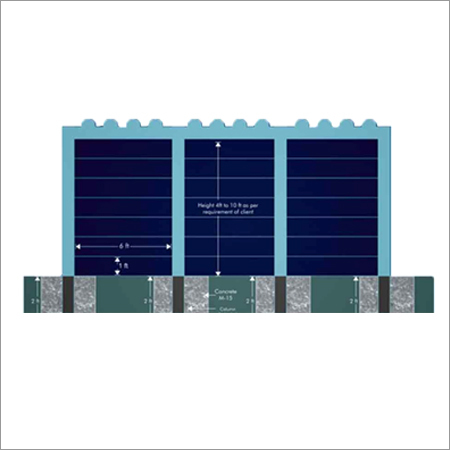

We are a matchless supplier and manufacturer of Affordable Pre-cast Compound Wall Mould. This is manufactured using modern technology, latest technology and optimum quality raw materials, which are attained from reliable sources of the industry. It is further made in compliance with set parameters of the domain in order to meet the preferences of the clients. Thus, we are reckoned as a ruling supplier and manufacturer of Affordable Pre-cast Compound Wall Mould. Moreover, this is also delivered in promised time frame.Features of Custom Compound Wall Mould:

- Durable

- High strength

- Seamless quality

- Fine finish

Technical Specifications:

|

No of Panels |

18 |

|

Material |

Iron |

|

Application |

Civil Works |

High-Precision Customisation

Our compound wall moulds are tailored to meet client specifications in size, design, logo placement, and surface finish. Advanced engineering ensures dimension accuracy and high-quality results, while a wide array of color and texture options allows for both practical and aesthetic flexibility.

Robust Industrial Performance

Manufactured with high-grade steel, alloy, stainless steel, and premium molding materials, these moulds are built to endure the rigors of continuous industrial and commercial applications. Their excellent corrosion resistance and thermal stability make them suitable for diverse operating environments.

Low Maintenance & Longevity

Designed for easy cleaning and simple upkeep, these moulds promise up to 10 years of reliable service with proper care. High tolerance and robust build guarantee up to 100,000 cycles, ensuring cost-effective and efficient production.

FAQs of Custom Compound Wall Mould:

Q: How can I customize the compound wall mould to meet my project requirements?

A: You can specify the moulds size, shape, surface finish (smooth, matte, or custom texture), color, and incorporate your company logo or design elements. Our team works closely with you to ensure the mould meets all your functional and visual expectations.Q: What materials and processes are used in manufacturing these moulds?

A: We use high-grade steel, alloy, and stainless steel for the mould base, and plastic, PVC, or concrete for molding. The shaping mode can be selected based on your needsincluding injection, compression, or castingensuring the final product is both precise and durable.Q: When is this mould suitable for use in industrial or commercial projects?

A: The mould is ideal for industrial and commercial precast compound wall panel production, especially where high precision, durability, and customization are crucial. Its robust construction and corrosion resistance support heavy-duty, frequent usage.Q: Where can these custom wall moulds be installed or utilized?

A: These moulds are used in precast production facilities or factories where compound wall panels are manufactured for installation at commercial, industrial, residential, or infrastructure sites across India and for export.Q: What benefits do these moulds offer in long-term production?

A: With a mould life of 50,000100,000 cycles and a lifespan of up to 10 years, you benefit from consistent quality, minimal downtime, and reduced replacement costs, ensuring a reliable return on your investment.Q: How should the moulds be maintained for optimal lifespan and performance?

A: Routine cleaning with non-abrasive materials and regular inspections to check for wear or damage are recommended. Proper lubrication and storage, along with adherence to application guidelines, will help achieve the optimal lifespan and consistent quality output.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Compound Wall Moulds Category

Compound Wall Pole Mould

Price 95 INR / Ton

Minimum Order Quantity : 1 Kilograms

Material : Other, Steel Alloy

Mold Base : High Quality Mild Steel

Shaping Mode : Other, Precast Mould

Tolerance : 1 mm

Iron Concrete Compound Wall Mould

Price 60 INR / Ton

Minimum Order Quantity : 1 Ton

Material : Other, Cast Iron

Mold Base : Iron

Shaping Mode : Other, Precast

Tolerance : 1 mm

Rcc Compound Wall Mould

Price 95 INR / Ton

Minimum Order Quantity : 1 Kilograms

Material : Other, Mild Steel/Alloy Steel

Mold Base : Fine Quality Steel

Shaping Mode : Compression Mould

Tolerance : 1 mm

Pre Cast Compound Wall Mould

Price 60 INR / Ton

Minimum Order Quantity : 1 Ton

Material : Other, ABS, Steel, FRP

Mold Base : Mild Steel / Cast Iron

Shaping Mode : Other, Precast Concrete Mould

Tolerance : 1 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS