Ready Made Compound Mould

Price 60 INR/ Ton

Ready Made Compound Mould Specification

- Life Span

- Up to 5-8 years

- Mold Base

- P20 Steel

- Cavity

- Single or Multi Cavity

- Molding Material

- PVC, Polycarbonate, HDPE

- Shaping Mode

- Plastic Injection Mould

- Material

- High Grade Steel

- Tolerance

- 0.02 mm

- Mould Weight

- 200-700 kg

- Mould Life

- Minimum 300,000 shots

- Customization

- Available

- Gate Type

- Edge/Sprue/Pin

- Manufacturing Process

- Precision CNC Machined

- Runner System

- Hot/Cold Runner

- Application

- Compound Wall Panel Production

- Surface Finish

- Polished or Textured

- Color

- Silver Grey

- Core/Cavity Hardness

- HRC 48-52

- Maintenance

- Low Maintenance Required

Ready Made Compound Mould Trade Information

- Minimum Order Quantity

- 1 Ton

- Average Load Time

- 45-60 seconds

- Supply Ability

- 15 Tons Per Day

- Delivery Time

- 1 Week

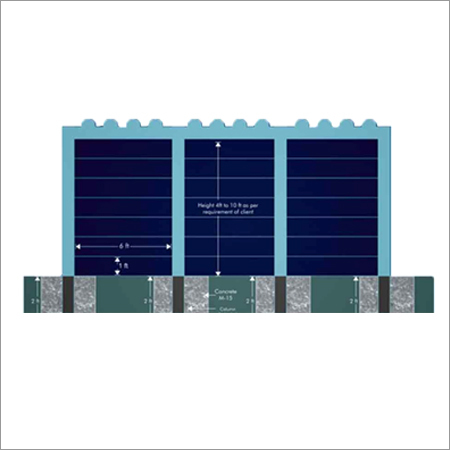

About Ready Made Compound Mould

Technical Specifications:

| Use | Gardens,Villas etc |

| Material | RCC |

| Built Type | Panel Build |

Superior Material and Accurate Shaping

Constructed with high-grade steel and a P20 steel base, this mould delivers core and cavity hardness of HRC 48-52, ensuring exceptional strength and longevity. It supports high-precision plastic injection molding with a 0.02 mm tolerance, suitable for PVC, polycarbonate, or HDPE materials, providing reliably shaped compound wall panels.

Customizable Design for Unique Projects

The mould can be tailored to specific requirements, from cavity options (single or multi) to surface finish (polished or textured) and gate type (edge, sprue, pin). With flexibility in runner systems and molding material compatibility, it accommodates a wide range of panel production needs, making it an adaptable asset for manufacturers.

Long Life Span and Minimal Maintenance

Engineered for durability, the mould offers a minimum operational guarantee of 300,000 shots and an overall lifespan of up to 5-8 years. Its precision manufacturing facilitates low maintenance, reducing operational downtime and cost over time. This reliability is ideal for high-volume wall panel production environments.

FAQs of Ready Made Compound Mould:

Q: How does the Ready Made Compound Mould benefit wall panel manufacturers?

A: The mould allows for efficient and consistent production of compound wall panels, thanks to its precision CNC machining, robust material selection, and customizable features. Its long lifespan and low maintenance requirements further enhance cost savings and operational reliability.Q: What materials can be used with this mould for wall panel production?

A: This compound mould is compatible with PVC, polycarbonate, and HDPE molding materials, providing manufacturers flexibility to choose the best material for their specific panel application.Q: When is customization available for the mould design or configuration?

A: Customization is available during the order process, allowing clients to specify requirements such as cavity count, surface finish, gate type, and runner system, ensuring the mould aligns with unique project needs.Q: Where is the Ready Made Compound Mould manufactured and exported from?

A: The mould is manufactured, supplied, and exported from India, with an established network serving manufacturers, suppliers, traders, and exporters globally.Q: What is the maintenance process for this compound mould?

A: The mould requires minimal maintenance due to its durable construction and precision engineering. Routine inspection and cleaning of the molding surfaces ensure optimal performance and extend the service life.Q: How long is the expected operational lifespan of the mould?

A: The mould is designed to last a minimum of 300,000 shots and typically provides a service life spanning 5 to 8 years, depending on usage and maintenance practices.Q: What runner and gate systems are supported by this mould?

A: The mould supports both hot and cold runner systems and accommodates edge, sprue, and pin gate types, offering versatility for different injection molding setups.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Compound Wall Moulds Category

Wall Mould

Price 60 INR / Ton

Minimum Order Quantity : 1 , , Ton

Material : Steel

Shaping Mode : Other

Molding Material : MS STEEL

Mould Life : 10 Years

Industrial Wall Mould

Price 60 INR / Ton

Minimum Order Quantity : 1 Ton

Material : Other, Hardened Tool Steel (P20, H13, 2738, etc.)

Shaping Mode : Injection Mould

Molding Material : Highgrade Plastic, Thermoset Polymers

Mould Life : 500,000 1,000,000 shots

Commercial Precast Compound Wall Mould

Price 60 INR / Ton

Minimum Order Quantity : 1 Ton

Material : Steel

Shaping Mode : Other, Precast Mould

Molding Material : Concrete

Mould Life : Up to 1,00,000 Cycles

Rcc Compound Wall Mould

Price 95 INR / Ton

Minimum Order Quantity : 1 Kilograms

Material : Other, Mild Steel/Alloy Steel

Shaping Mode : Compression Mould

Molding Material : Highgrade Concrete

Mould Life : 80,000+ cycles

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS