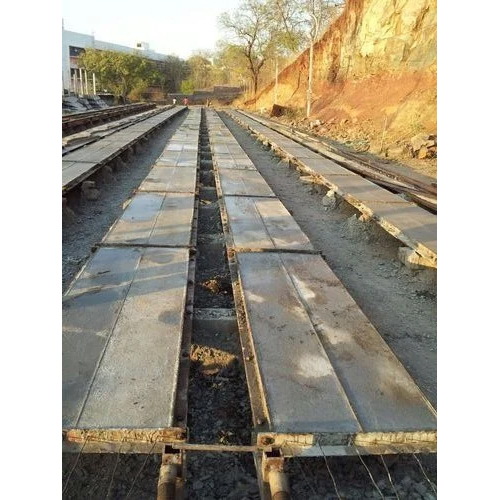

Commercial Precast Compound Wall Mould

Price 60 INR/ Ton

Commercial Precast Compound Wall Mould Specification

- Life Span

- 8-10 Years

- Mold Base

- Mild Steel

- Molding Material

- Concrete

- Cavity

- Single

- Shaping Mode

- Precast Mould

- Material

- Steel

- Tolerance

- 0.1 mm

- Mould Weight

- Approx. 150-250 Kg

- Mould Life

- Up to 1,00,000 Cycles

- Wall Thickness

- 50 - 75 mm (customizable)

- Color

- Natural/Metallic Grey

- Length of Panel Cast

- Up to 10 ft (customizable)

- Working Temperature

- -10°C to +45°C

- Width of Panel Cast

- Up to 300 mm (customizable)

- Maintenance

- Low Maintenance, Easy Cleaning

- Usage/Application

- Commercial Compound Wall Production

- Feature

- High Dimensional Accuracy, Easy Demolding, Durable Structure, Corrosion Resistant, Reusable

- Manufacturing Technique

- Precision Fabrication & CNC Cutting

- Surface Finish

- Polished/Anti-Rust Coated

Commercial Precast Compound Wall Mould Trade Information

- Minimum Order Quantity

- 1 Ton

- Average Load Time

- 2-4 Minutes Per Cycle

- Supply Ability

- 15 Tons Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard

- Main Domestic Market

- All India

About Commercial Precast Compound Wall Mould

Our establishment is a distinguished supplier and manufacturer of unified Customized Pre-cast Compound Wall Mould. It is easy to maintain, highly durable in nature, most affordable, and easy to use. This is manufactured by our experts in accordance with the latest norms of the field. Thus, this is widely appreciated among the clients, apart from this, in order to suit the numerous needs of the customers, we manufacture Customized Pre-cast Compound Wall Mould in diverse sizes and specifications.Customized Pre-cast Compound Wall Mould Features:

- Seamless

- Rugged construction

- Reliable

- Excellent quality

Precision Manufacturing for Maximum Durability

Engineered through advanced precision fabrication and CNC cutting, our precast wall moulds meet stringent industry standards. The use of high-grade steel and an anti-rust polished surface ensures long-term durability, even in demanding commercial environments.

Customizable Dimensions for Versatile Projects

Our molds accommodate a variety of panel sizeswith customizable length (up to 10 ft), width (up to 300 mm), and wall thickness (5075 mm). This flexibility enables you to meet specific project requirements, ensuring readiness for a range of commercial applications.

Low Maintenance and Easy Demolding

Designed for convenience, our moulds allow for effortless demolding of concrete panels, significantly reducing cycle times. Their corrosion-resistant surface and robust construction make cleaning and ongoing maintenance both simple and cost-effective.

FAQs of Commercial Precast Compound Wall Mould:

Q: How is the Commercial Precast Compound Wall Mould used in wall production?

A: The mould is filled with concrete and set in a controlled environment. Once the concrete sets, the easy demolding feature allows quick removal of the finished panel, streamlining production for commercial projects.Q: What customized options are available for the mould dimensions?

A: You can customize the mould to cast panels up to 10 feet in length, up to 300 mm in width, and with wall thicknesses ranging from 50 to 75 mm, catering to diverse commercial project needs.Q: What benefits does the polished or anti-rust coated surface provide?

A: The polished or anti-rust coated surface enhances durability by preventing corrosion. It also ensures smoother finishes for the cast panels and reduces maintenance effort.Q: What is the typical life span and mould cycle life?

A: Each mould is engineered for longevity, with a typical use life of 810 years and up to 100,000 casting cycles under standard operating conditions.Q: How easy is it to maintain and clean the precast wall mould?

A: Maintenance is minimal due to the moulds corrosion-resistant, polished surface. Cleaning is straightforward, supporting frequent and prolonged use with little downtime.Q: Where is this product manufactured and supplied from?

A: The moulds are manufactured, exported, and supplied from India, ensuring adherence to quality standards and offering reliable service to commercial clients worldwide.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Compound Wall Moulds Category

Iron Concrete Compound Wall Mould

Price 60 INR / Ton

Minimum Order Quantity : 1 Ton

Material : Other, Cast Iron

Mold Base : Iron

Mould Life : 50008000 cycles

Molding Material : Concrete

Industrial Wall Mould

Price 60 INR / Ton

Minimum Order Quantity : 1 Ton

Material : Other, Hardened Tool Steel (P20, H13, 2738, etc.)

Mold Base : Standardized Steel Base

Mould Life : 500,000 1,000,000 shots

Molding Material : Highgrade Plastic, Thermoset Polymers

Pre Cast Compound Wall Mould

Price 60 INR / Ton

Minimum Order Quantity : 1 Ton

Material : Other, ABS, Steel, FRP

Mold Base : Mild Steel / Cast Iron

Mould Life : 50,000 cycles or more

Molding Material : High Quality Steel

Prestressed Precast Compound Wall Mould

Price 75 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Material : Iron

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS