Pre Cast Compound Wall Mould

Price 60 INR/ Ton

Pre Cast Compound Wall Mould Specification

- Cavity

- Single / Multiple as per requirement

- Life Span

- 5-10 Years

- Mold Base

- Mild Steel / Cast Iron

- Molding Material

- High Quality Steel

- Shaping Mode

- Precast Concrete Mould

- Material

- ABS, Steel, FRP

- Tolerance

- 1 mm

- Mould Weight

- Approx. 80-150 kg

- Mould Life

- 50,000 cycles or more

Pre Cast Compound Wall Mould Trade Information

- Minimum Order Quantity

- 1 Ton

- Average Load Time

- 3-5 min

- Supply Ability

- 15 Tons Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Standard

- Main Domestic Market

- All India

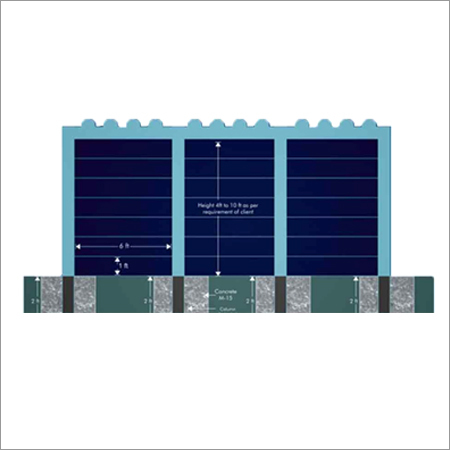

About Pre Cast Compound Wall Mould

Pre-cast Compound Wall Mould (PR)1 provided by us is made under the supervision of experts using advanced technology and quality assured raw materials. Therefore, we are applauded as a noted supplier and manufacturer of the domain. It is also manufactured at budget friendly prices in stipulated time frame in a variety of sizes, specifications and colors as per the needs of the valued customers. Owing to all, our offered Pre-cast Compound Wall Mould (PR)1 is massively in demand.

Pre-cast Compound Wall Mould Features:

- Lightweight

- Noted quality

- Durable

- Fine finish

Technical Specifications:

|

Available Material |

Iron and Steel |

|

Shape |

Rectangular |

|

Application |

Civil Works |

High Durability & Low Maintenance

Crafted from high-quality materials such as mild steel, cast iron, ABS, and FRP, these pre cast compound wall moulds are built for heavy-duty use. They offer excellent corrosion resistance and withstand frequent usage, requiring very little maintenance throughout their service life. The typical mould lifespan ranges from 5 to 10 years, minimizing replacement costs and downtime.

Customizable & Precise Manufacturing

Each mould can be fully customized according to client specifications, including wall height, color, cavity configuration, and material choice. With a manufacturing tolerance of 1 mm, the moulds consistently produce precise wall sections. Whether you prefer single or multiple cavities, the design flexibility ensures seamless integration into your precast wall production line.

User-Friendly Design for Efficient Operation

Designed for compatibility with vibrating tables and featuring a reusable, heavy-duty structure, these moulds significantly improve production efficiency. Their surface finish ensures walls have a smooth or polished appearance straight out of the mould. The user-centric design also facilitates quick demoulding and easy handling, saving time at every step of the manufacturing process.

FAQs of Pre Cast Compound Wall Mould:

Q: How do I use the Pre Cast Compound Wall Mould in my manufacturing process?

A: Simply prepare your concrete mix, pour it into the mouldcompatible with vibrating tables for compactionand allow it to cure. Once set, the moulds surface finish allows for easy demoulding, ensuring each wall section comes out smooth and uniform.Q: What customization options are available for the compound wall moulds?

A: We offer customisation in terms of mould height, thickness, cavity configuration, color, and material (ABS, steel, or FRP), as well as finish and mold base. You can specify your preferences to match unique project requirements or architectural designs.Q: When should these moulds be replaced or maintained?

A: Generally, these heavy-duty moulds have a lifespan of 510 years or up to 50,000 cycles. Maintenance is minimal due to high-quality materials and corrosion resistance, but routine checks after each use are recommended to ensure longevity and consistent moulding quality.Q: Where are these moulds manufactured and supplied from?

A: We are based in India and serve as an exporter, manufacturer, supplier, and trader. Our moulds are supplied domestically and internationally, packaged securely in wooden boxes or plastic wraps to ensure safe delivery.Q: What benefits do these moulds provide compared to alternatives?

A: These pre cast compound wall moulds offer a polished, uniform surface finish, high structural accuracy, and significant cost efficiency due to reusability and long operational life. Their compatibility with standard manufacturing equipment and low maintenance needs further enhance overall productivity.Q: How does the mould cope with varying wall designs and thicknesses?

A: Our moulds are fully customizable, supporting standard wall heights of 68 feet and mould thickness between 816 mm. We can manufacture moulds tailored to your unique design specifications, ensuring flexibility for different architectural requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Compound Wall Moulds Category

Wall Mould

Price 60 INR / Ton

Minimum Order Quantity : 1 , , Ton

Shaping Mode : Other

Molding Material : MS STEEL

Material : Steel

Mould Weight : 100 kg to 1250 Kg Kilograms (kg)

Rcc Compound Wall Mould

Price 95 INR / Ton

Minimum Order Quantity : 1 Kilograms

Shaping Mode : Compression Mould

Molding Material : Highgrade Concrete

Material : Other, Mild Steel/Alloy Steel

Mould Weight : 80120 kg (Approx.)

Custom Compound Wall Mould

Price 60 INR / Ton

Minimum Order Quantity : 1 , , Ton

Shaping Mode : Other, Injection / Compression / Casting

Molding Material : Plastic / PVC / Concrete

Material : Other, HighGrade Steel / Alloy

Mould Weight : 80150 kg (depending on size)

Compound Wall Pole Mould

Price 95 INR / Ton

Minimum Order Quantity : 1 Kilograms

Shaping Mode : Other, Precast Mould

Molding Material : Concrete, RCC

Material : Other, Steel Alloy

Mould Weight : 3850 Kg (depending on size)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS